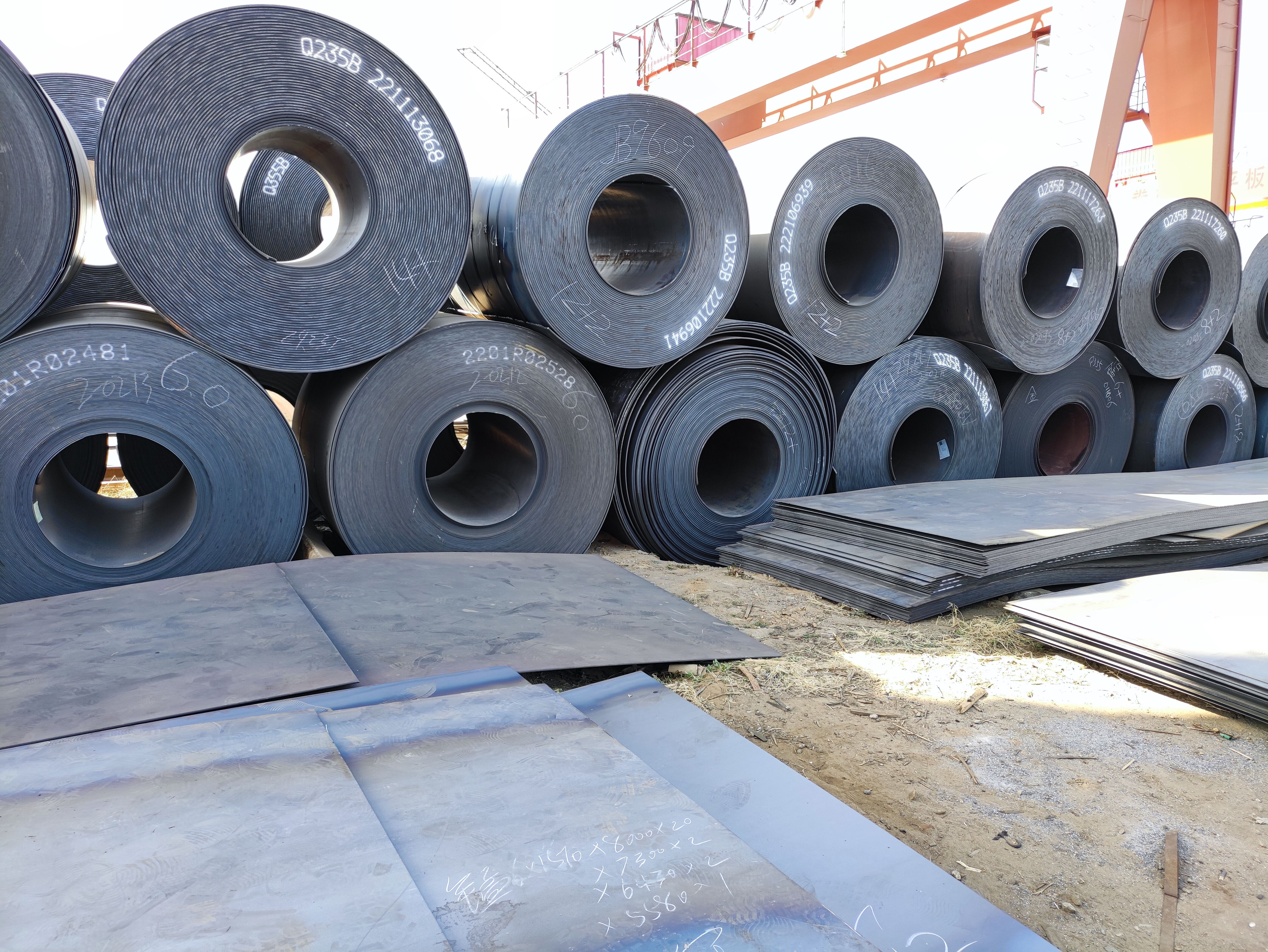

mild steel hot rolled coil

Mild steel hot rolled coil represents a fundamental product in the steel manufacturing industry, characterized by its versatile nature and cost-effective production process. This material undergoes a manufacturing process where steel is heated above its recrystallization temperature and then processed through a series of rollers, resulting in a coiled format that offers both convenience and efficiency in handling. The hot rolling process enhances the steel's mechanical properties, producing a material with improved strength and formability. These coils typically feature a carbon content of 0.05% to 0.25%, making them ideal for various industrial applications. The surface finish of hot rolled coils exhibits a characteristic dark blue-gray scale, which can be further processed depending on specific requirements. These coils are available in various thicknesses, typically ranging from 1.2mm to 25mm, and widths up to 2500mm, offering flexibility in application. The material's structural integrity, combined with its excellent welding properties and machinability, makes it a preferred choice in construction, automotive manufacturing, and general fabrication industries.