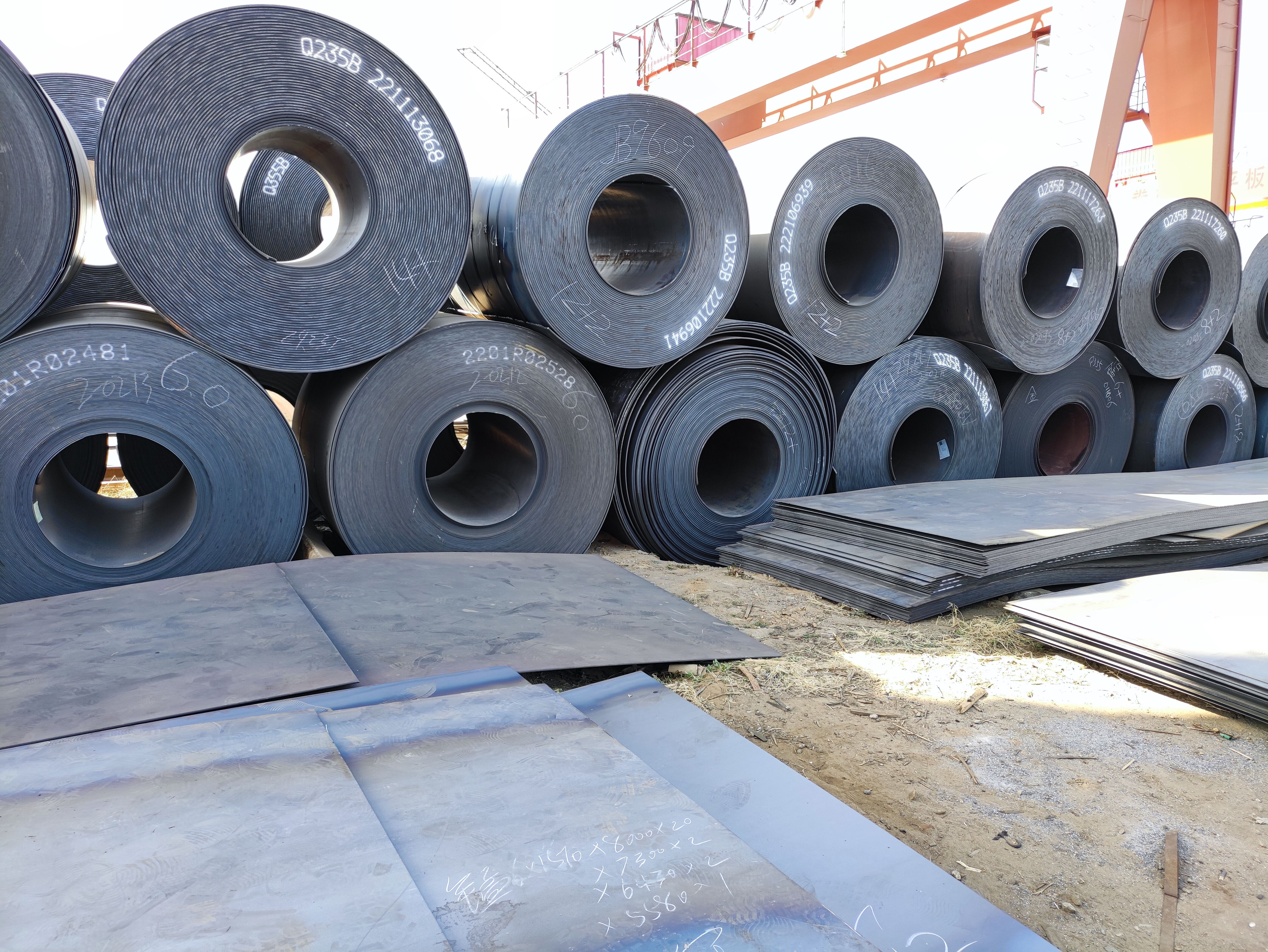

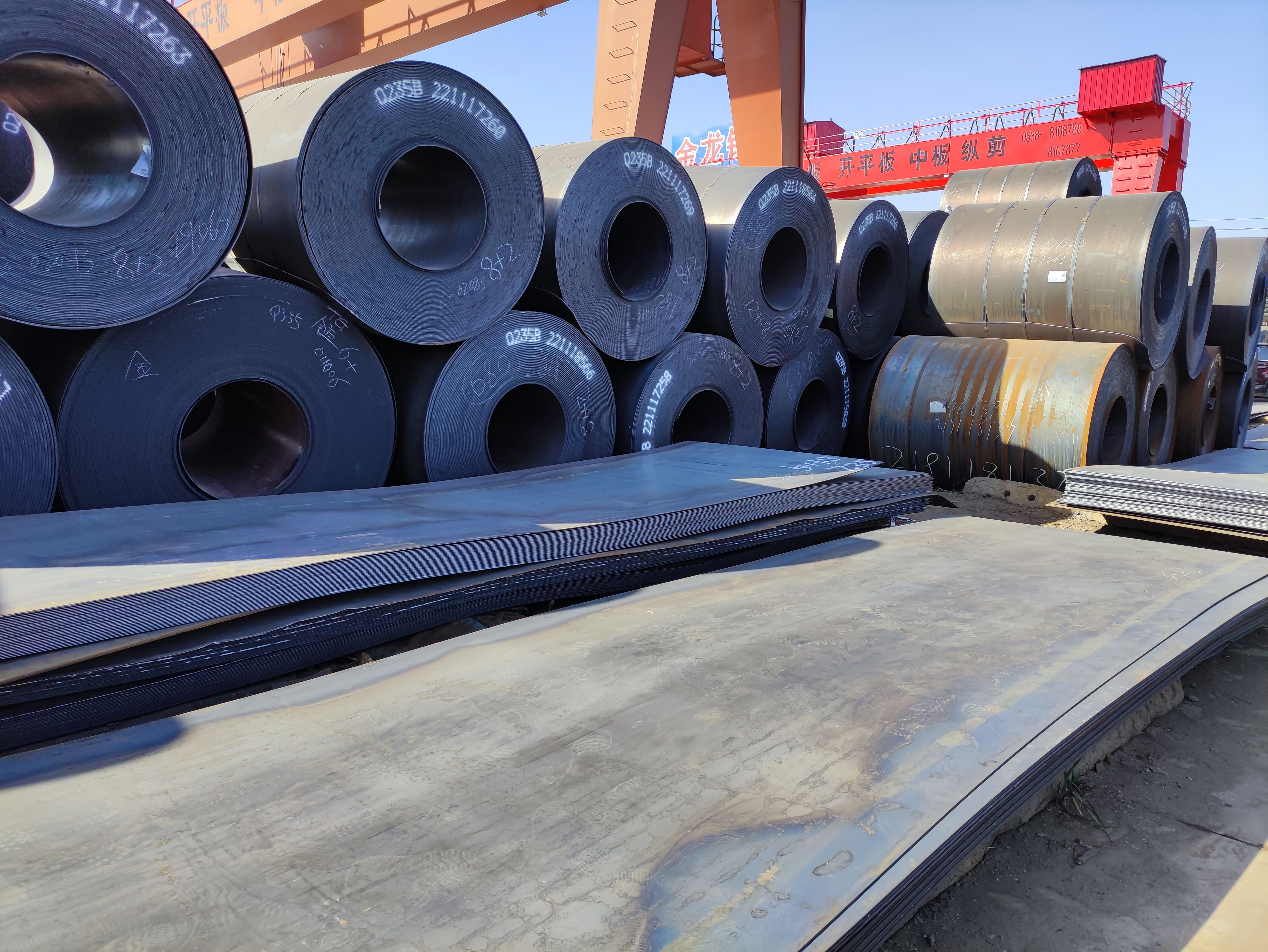

hot rolled alloy carbon steel coil

Hot rolled alloy carbon steel coil represents a fundamental material in modern manufacturing, engineered through a sophisticated thermal and mechanical process. This versatile product is manufactured by heating steel to temperatures exceeding 1700°F, followed by controlled rolling and cooling procedures that enhance its mechanical properties. The resulting material exhibits exceptional strength-to-weight ratios, superior formability, and remarkable durability. These coils are characterized by their uniform chemical composition, which typically includes carefully balanced proportions of carbon and other alloying elements such as manganese, chromium, and nickel. The manufacturing process ensures consistent material properties throughout the coil, making it ideal for various industrial applications. The surface finish, while not as refined as cold-rolled products, provides excellent adherence for subsequent coating processes and is particularly suitable for applications where precise dimensional tolerances are not critical. In industrial settings, these coils serve as essential raw materials for various manufacturing processes, including automotive components, construction materials, and heavy equipment fabrication.