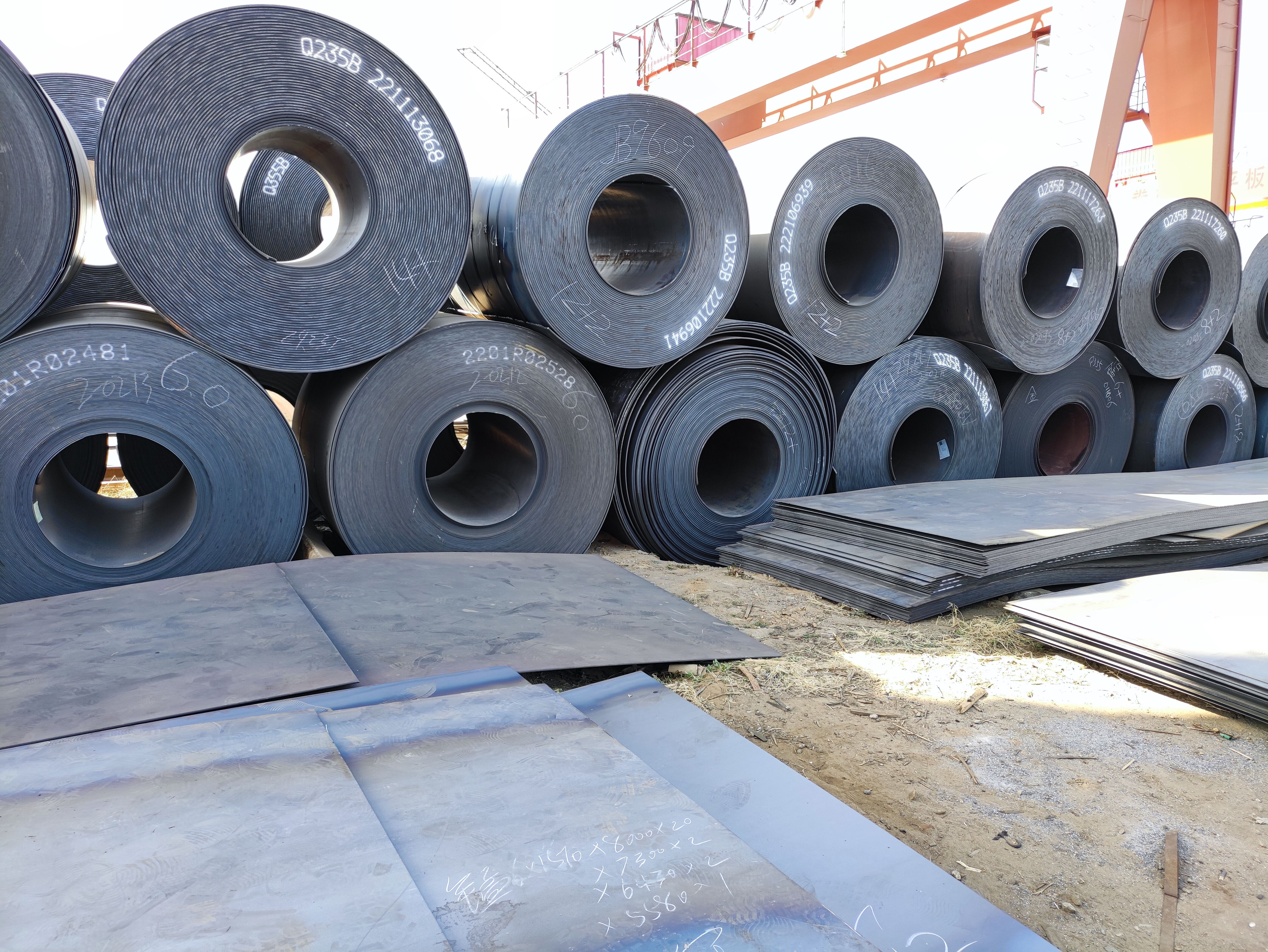

steel coil

Steel coils represent a fundamental form of processed steel that serves as the backbone of numerous manufacturing and construction applications. These cylindrical formations of continuous steel strips are produced through advanced rolling processes, where molten steel is carefully transformed into thin sheets and wound into compact, transportable coils. The thickness, width, and material grade of steel coils can be precisely controlled to meet specific industrial requirements. These versatile products undergo various treatments, including hot-rolling, cold-rolling, and galvanizing processes, to enhance their physical and chemical properties. Steel coils are engineered to provide optimal strength-to-weight ratios, corrosion resistance, and formability, making them essential in automotive manufacturing, construction, appliance production, and infrastructure development. Their uniform composition and consistent quality ensure reliable performance across diverse applications, from structural components to decorative finishes. The coiled format also facilitates efficient storage, transportation, and processing, allowing manufacturers to optimize their production workflows and reduce material handling costs.