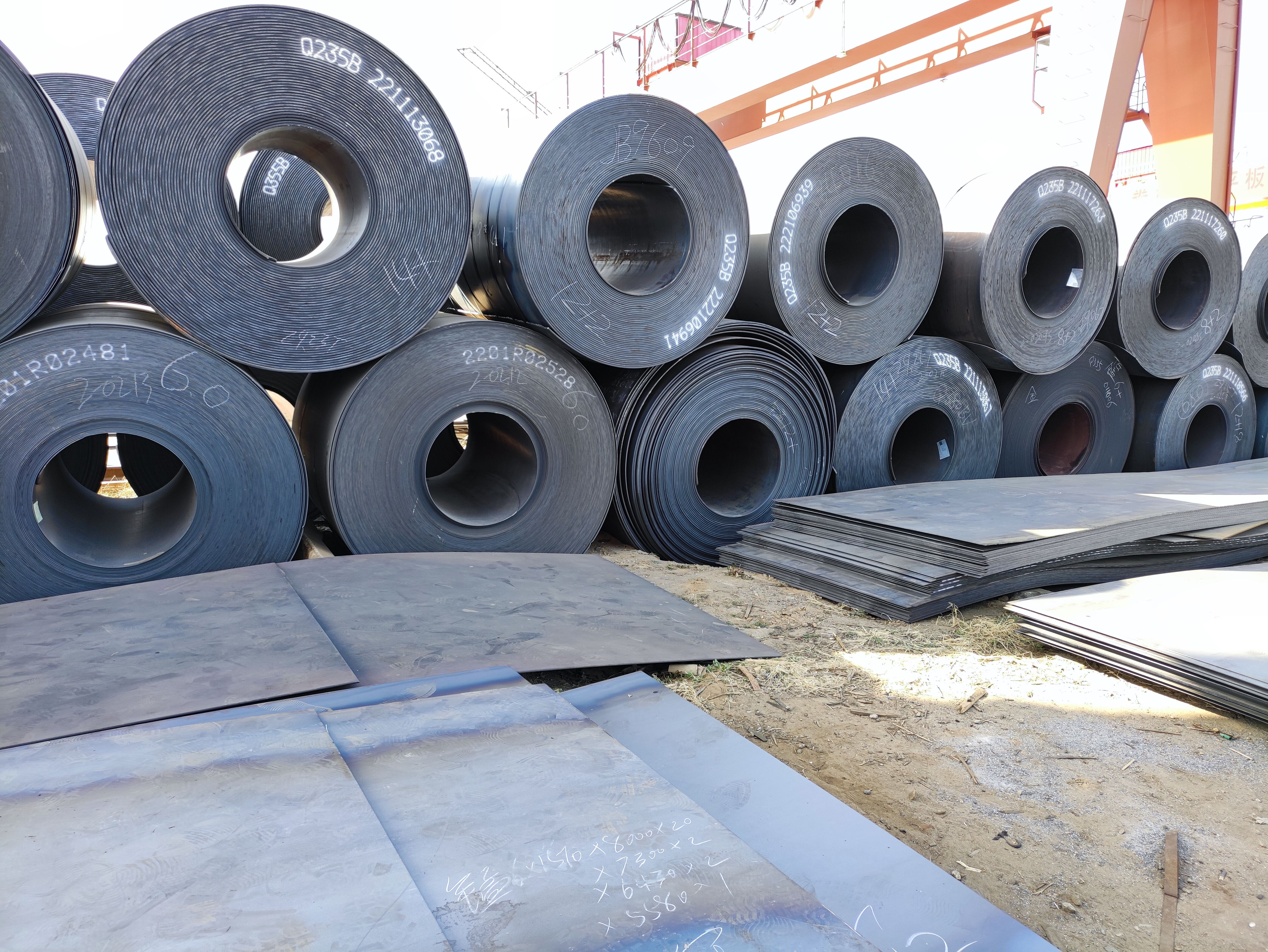

mild steel coils

Mild steel coils represent a fundamental component in modern manufacturing and construction industries, offering exceptional versatility and reliability. These coils are crafted through a precise rolling process that transforms raw steel into uniform, continuous strips with controlled thickness and width specifications. The carbon content typically ranges between 0.05% to 0.25%, striking an optimal balance between strength and workability. Mild steel coils exhibit remarkable formability, allowing them to be shaped, bent, and processed into various configurations without compromising structural integrity. These coils undergo rigorous quality control measures, including surface treatment and coating applications, to enhance corrosion resistance and extend service life. The manufacturing process incorporates advanced rolling technology and heat treatment protocols to ensure consistent mechanical properties throughout the material. Their applications span across multiple sectors, including automotive manufacturing, construction, infrastructure development, and industrial equipment fabrication. The coils serve as primary materials for producing pipes, tubes, sheets, and various structural components. Modern production facilities utilize state-of-the-art equipment to maintain precise dimensional tolerances and surface finish requirements, ensuring that each coil meets specific industry standards and customer specifications.