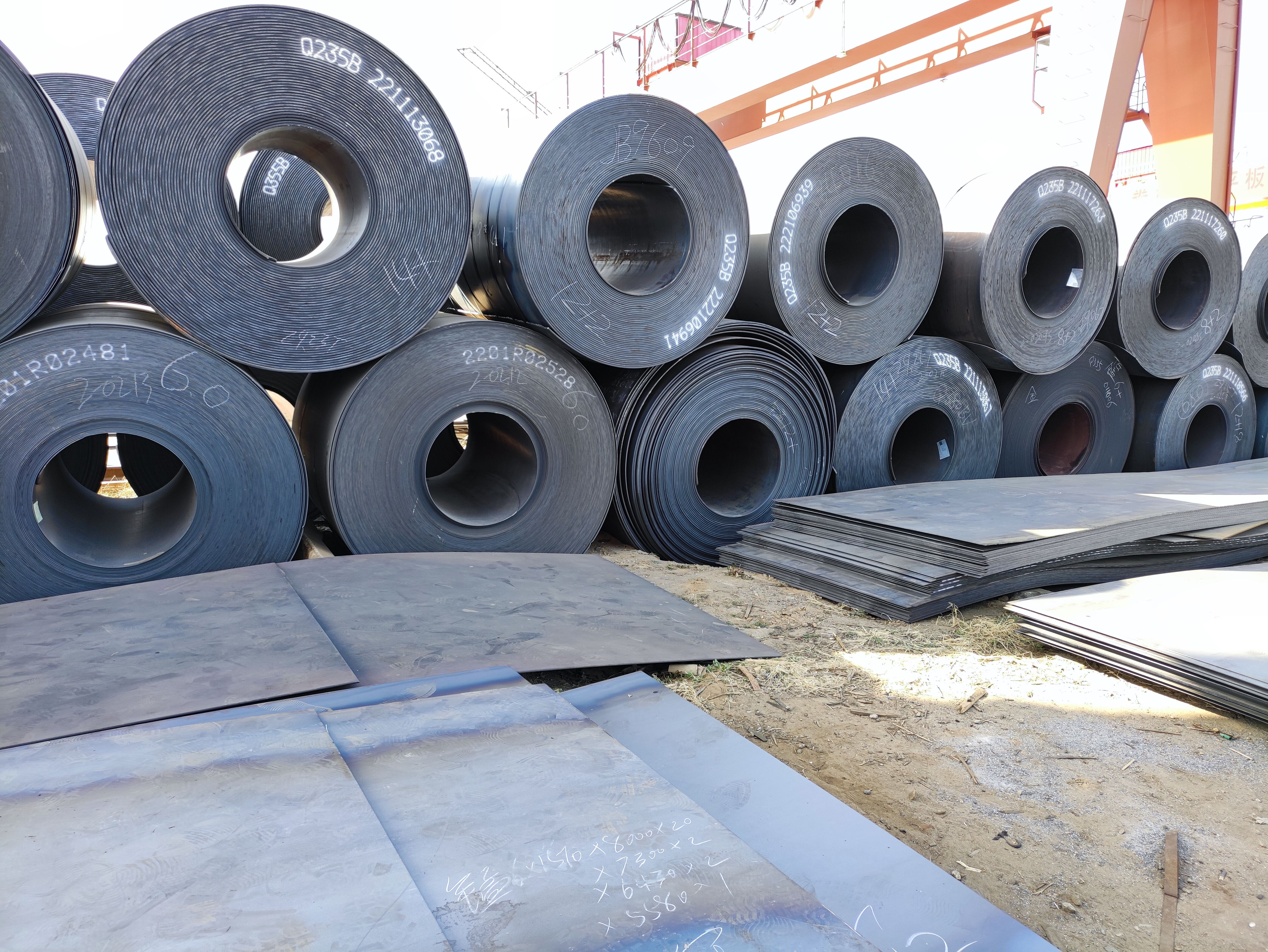

low carbon steel coils

Low carbon steel coils represent a fundamental material in modern manufacturing, characterized by their carbon content typically ranging between 0.05% to 0.25%. These versatile steel products combine excellent formability with reliable strength properties, making them ideal for numerous industrial applications. The manufacturing process involves careful control of temperature and cooling rates to achieve optimal mechanical properties. These coils are produced through continuous casting and hot rolling processes, ensuring consistent quality throughout the material. The steel's microstructure features a fine-grained ferrite-pearlite composition, contributing to its superior workability and surface finish. Low carbon steel coils offer exceptional weldability and are particularly suitable for cold forming operations. They demonstrate remarkable resistance to atmospheric corrosion when properly treated and can be easily machined or formed into various shapes. The material's adaptability makes it perfect for applications in construction, automotive manufacturing, and household appliances. These coils are available in various dimensions and specifications, accommodating different industrial requirements. Their cost-effectiveness, combined with reliable performance characteristics, has established them as a preferred choice in numerous manufacturing sectors.