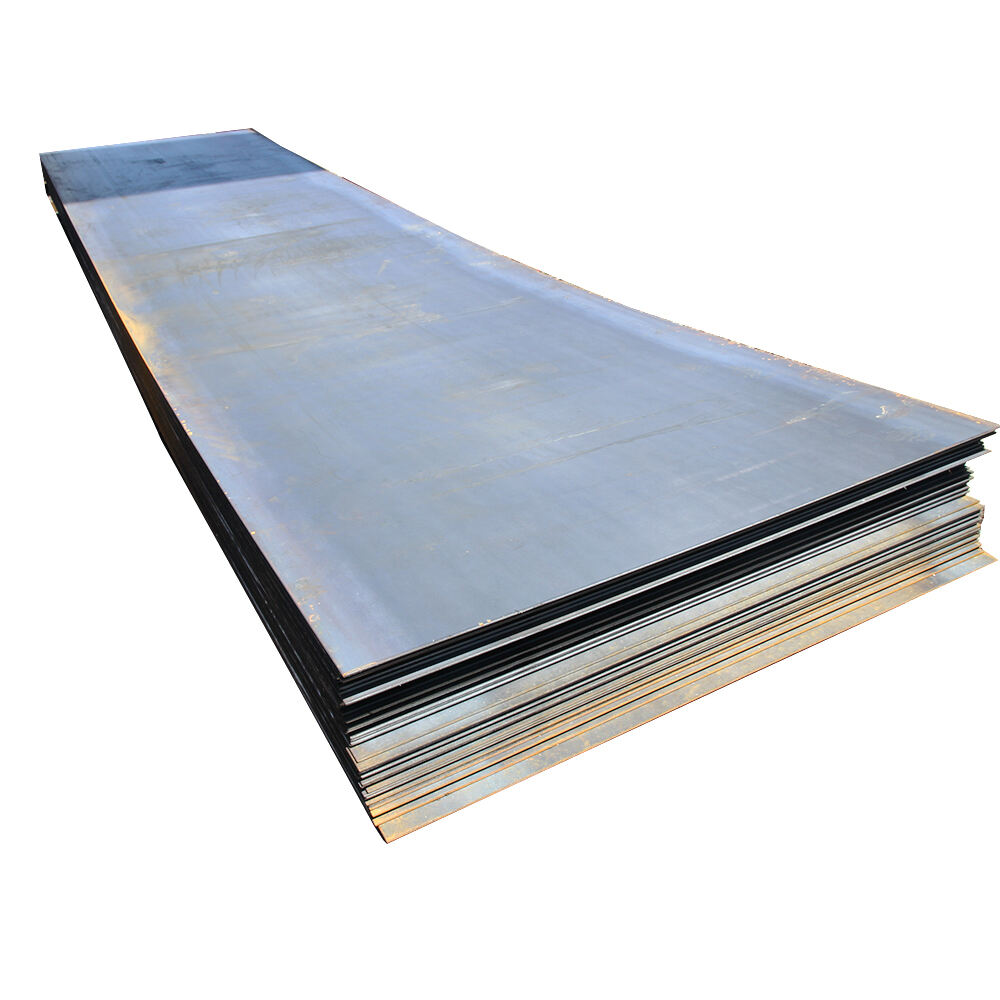

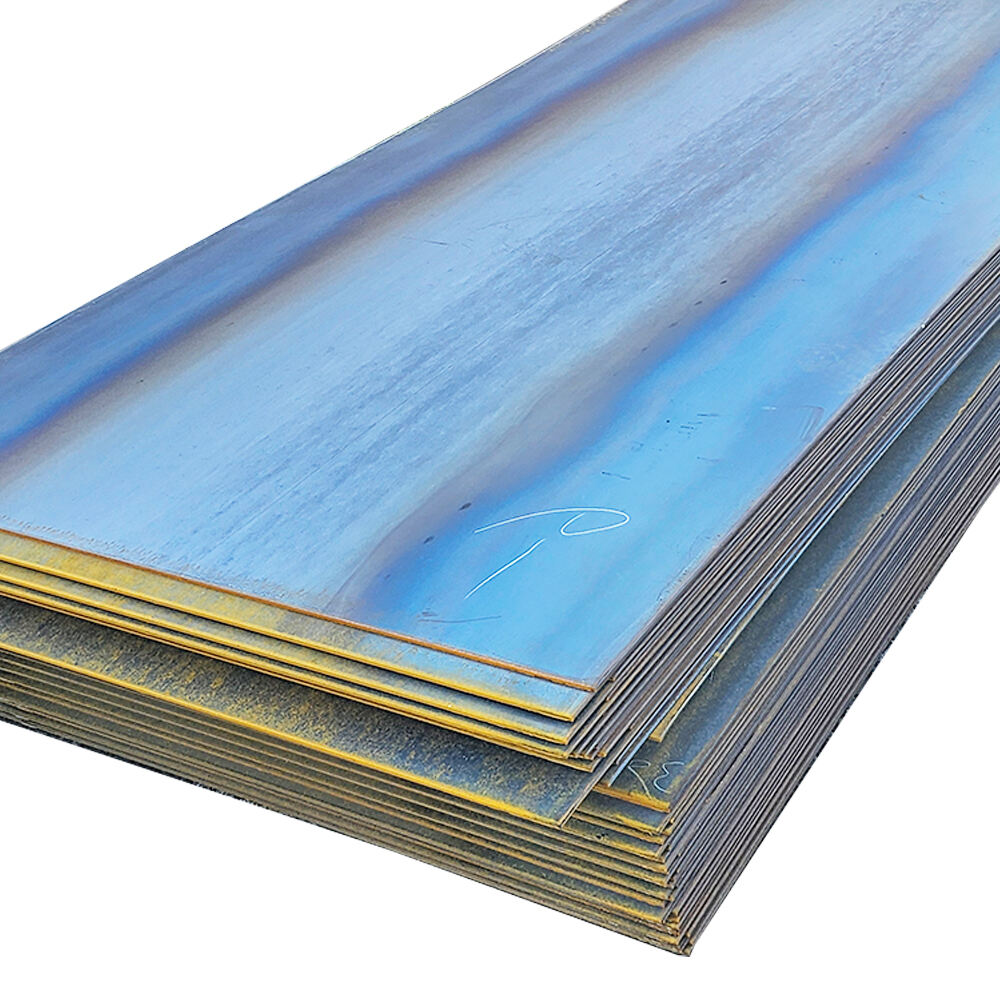

low carbon steel sheet metal

Low carbon steel sheet metal is a versatile and widely used material in manufacturing and construction industries, containing carbon content typically ranging between 0.05% to 0.25%. This composition provides an optimal balance of strength, formability, and cost effectiveness. The material undergoes specific manufacturing processes, including hot rolling and cold rolling, to achieve desired thickness and surface finish. These sheets exhibit excellent weldability and machinability, making them ideal for various fabrication methods. The material's inherent properties allow for easy forming, bending, and shaping without compromising structural integrity. Low carbon steel sheet metal finds extensive applications in automotive body panels, construction materials, appliance housings, and general manufacturing components. Its uniform grain structure ensures consistent performance across the sheet, while its surface characteristics make it suitable for various coating and finishing processes. The material's reliability in maintaining dimensional stability during processing, combined with its resistance to everyday wear and tear, makes it a practical choice for both industrial and commercial applications. Additionally, these sheets offer good heat conductivity and electrical properties, expanding their utility across different sectors.