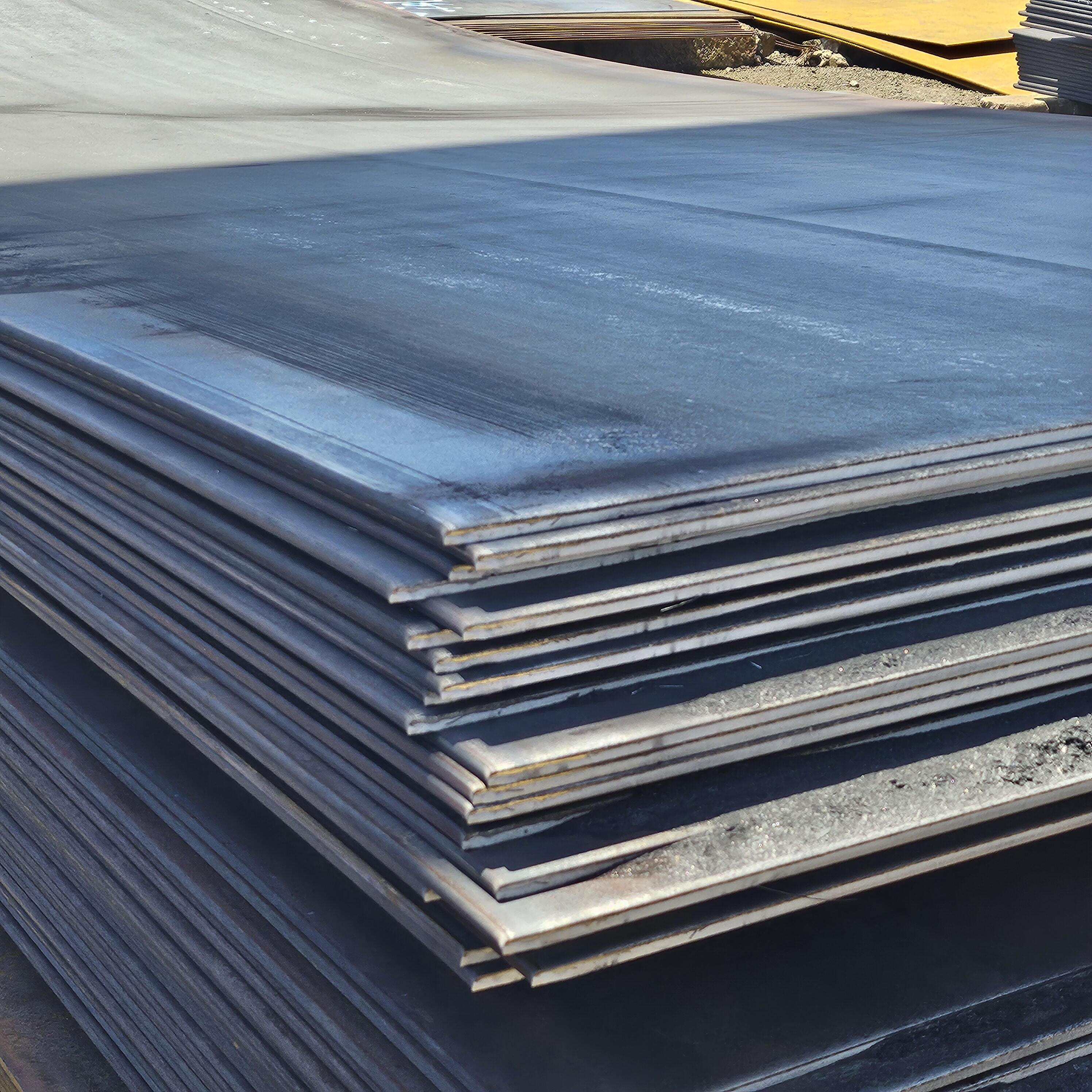

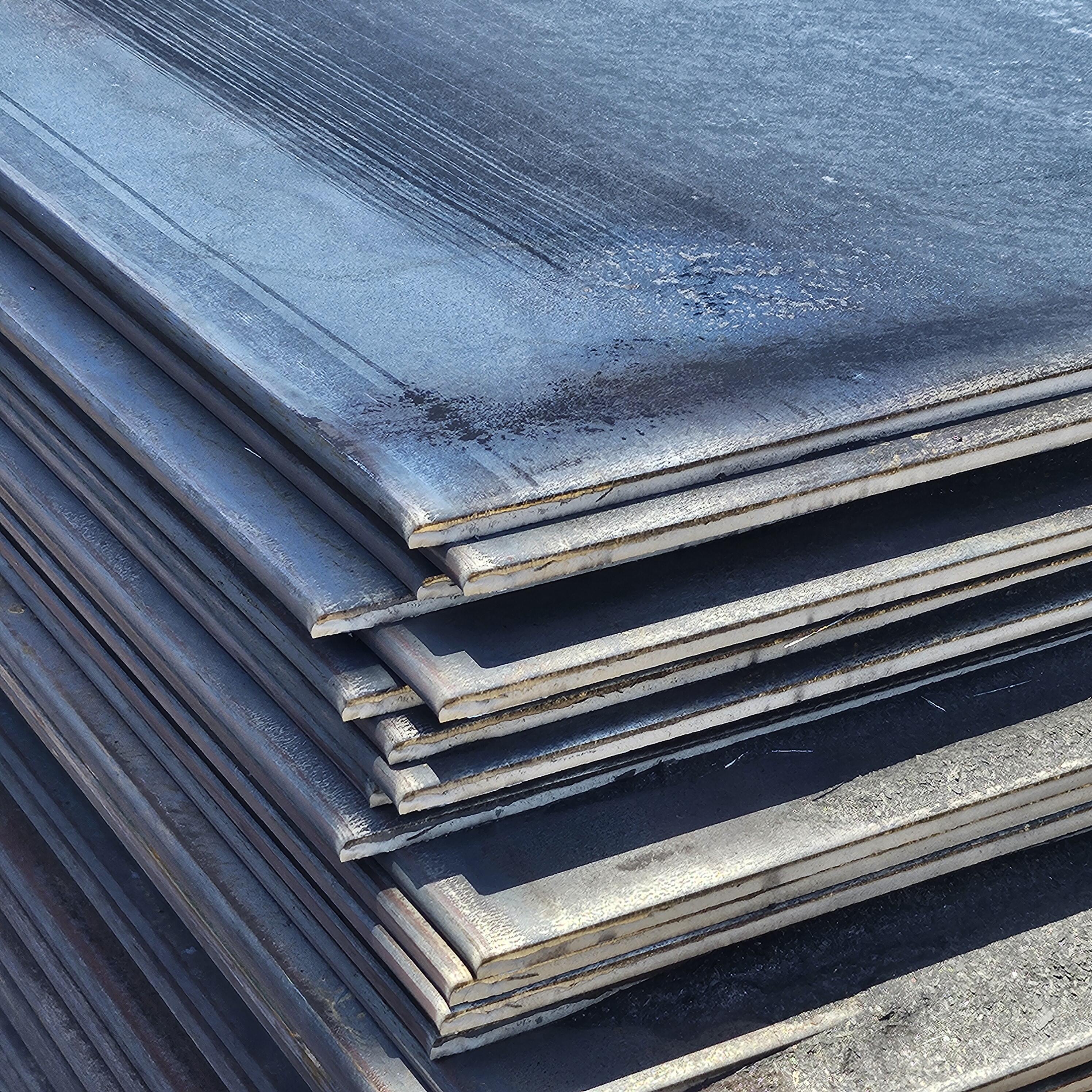

hot rolled carbon steel sheet

Hot rolled carbon steel sheet represents a fundamental material in modern manufacturing and construction industries. This versatile product is created through a high-temperature rolling process where steel is heated above its recrystallization temperature, typically around 1,700°F, and then processed through a series of rollers to achieve the desired thickness. The process results in a material that exhibits excellent formability, weldability, and cost-effectiveness. These sheets are characterized by their slightly rough surface finish, good strength-to-weight ratio, and dimensional consistency. The manufacturing process allows for various thickness options, typically ranging from 1.2mm to 25mm, making it suitable for diverse applications. In industrial settings, hot rolled carbon steel sheet serves as a primary material for construction frameworks, automotive components, and heavy machinery parts. The material's inherent properties make it particularly valuable in applications requiring structural integrity and durability. Its chemical composition, primarily consisting of iron and carbon with minimal alloying elements, contributes to its excellent mechanical properties while maintaining cost efficiency. The material's versatility extends to its ability to be further processed through secondary operations such as bending, welding, and machining, making it a preferred choice for manufacturers across various sectors.