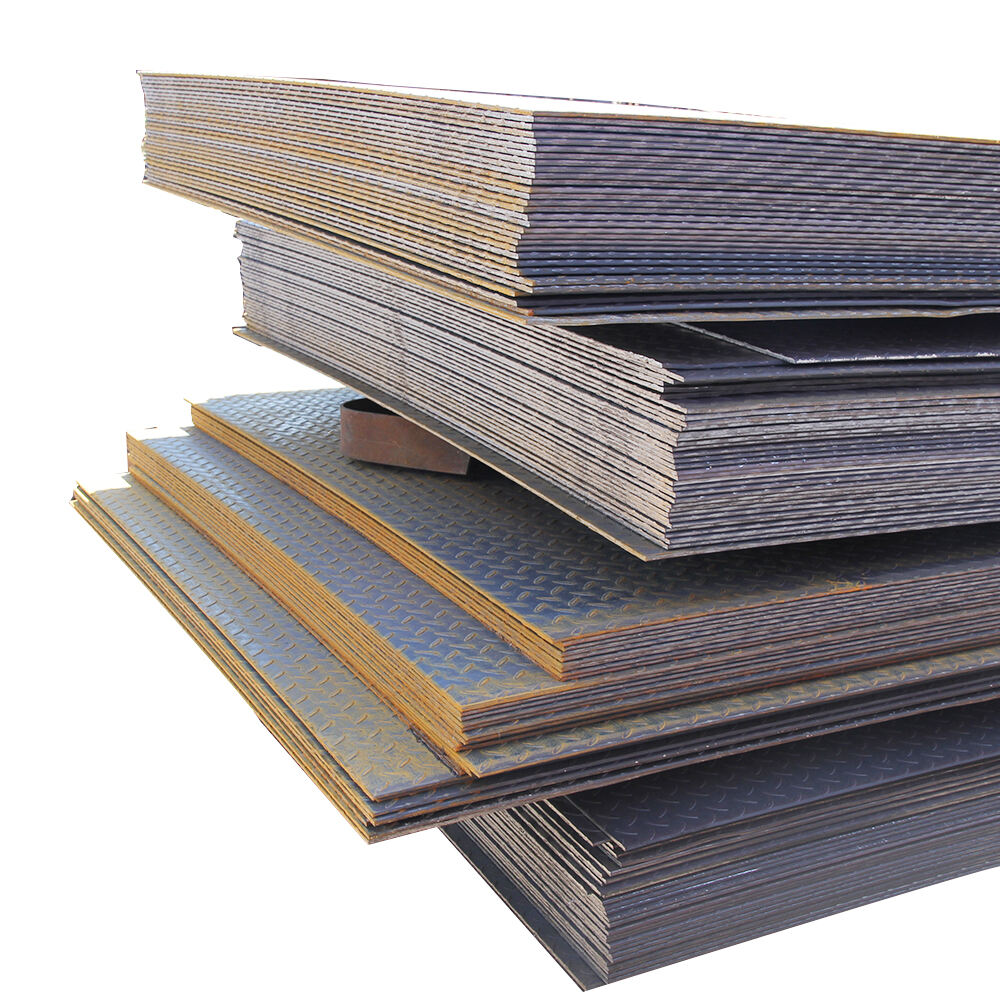

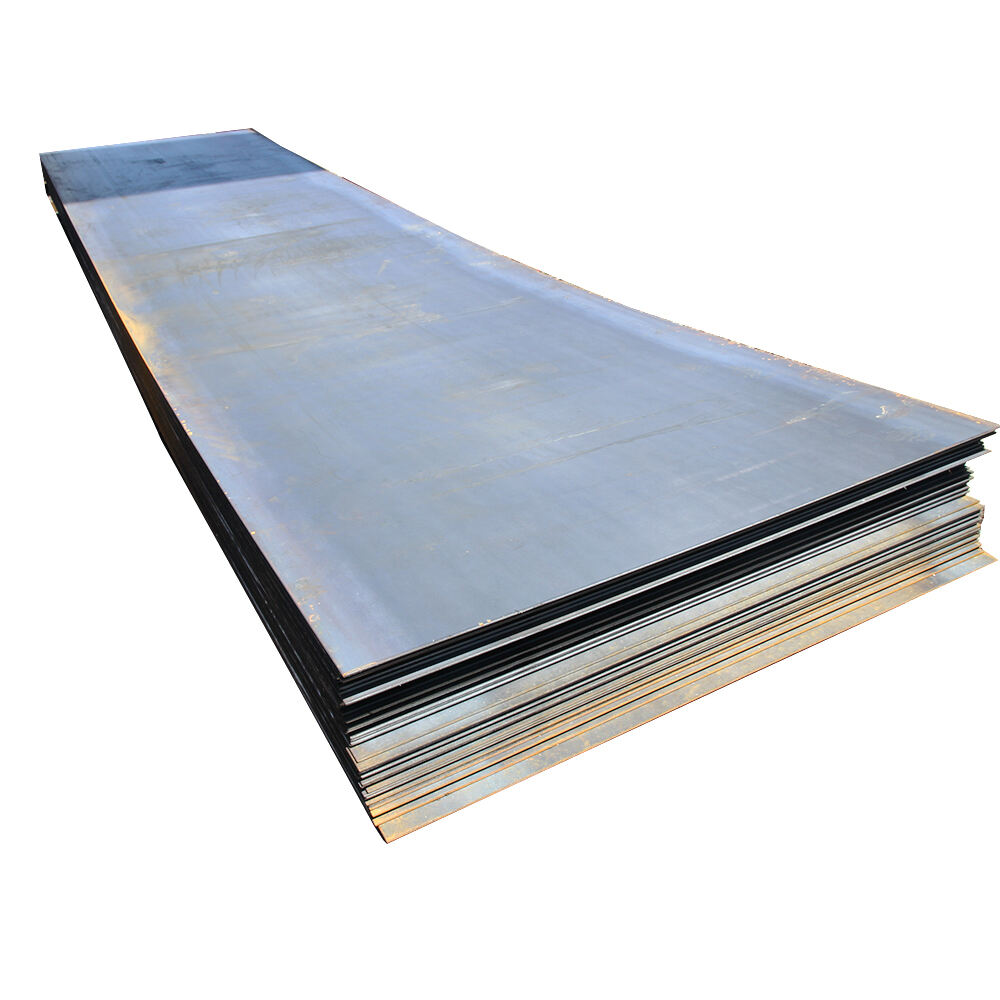

low carbon steel sheet

Low carbon steel sheet is a versatile and widely used material in manufacturing and construction, characterized by its carbon content typically ranging between 0.05% and 0.25%. This fundamental construction material offers an optimal balance of strength, formability, and cost-effectiveness. The manufacturing process involves carefully controlled rolling and cooling procedures, resulting in a uniform microstructure that ensures consistent performance across the entire sheet. These sheets are available in various thicknesses and dimensions, making them suitable for diverse applications. The material exhibits excellent weldability and machinability, allowing for easy fabrication and modification to meet specific project requirements. Low carbon steel sheets demonstrate remarkable durability in standard environmental conditions and can be further enhanced through various surface treatments and coatings. They are particularly valued in industries requiring large-scale metal forming operations, as they can withstand significant deformation without compromising structural integrity. The material's inherent properties make it ideal for applications ranging from automotive body panels and structural components to household appliances and construction elements. Additionally, these sheets can be easily recycled, contributing to sustainable manufacturing practices and reduced environmental impact.