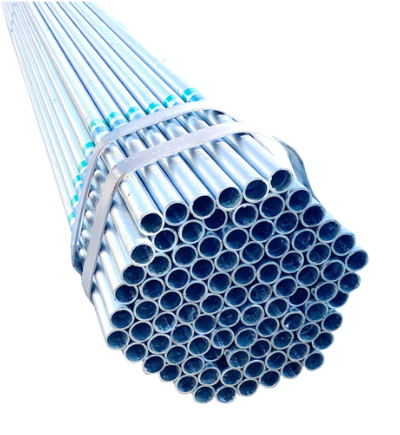

Превосходная коррозионная стойкость нержавеющей стали 304 Стальные трубы

Состав хром-никель для оптимальной защиты

трубы из нержавеющей стали 304 известны своим отличным сопротивлением коррозии и окислению, эти марки являются идеальным выбором для того, почему нержавеющая сталь, с её содержанием xx% хрома и xx% никеля в составе, является ответом. Обычно эти трубы содержат около 18% хрома и 8% никеля, что в сочетании делает трубы высокоустойчивыми к коррозии и окислению. Этот сплав укрепляет материал и защищает его свойства в различных условиях применения. Именно эти характеристики делают её такой популярной для промышленного использования, особенно там, где есть коррозионные элементы, такие как солёная вода или химикаты. Стоит отметить, что нержавеющая сталь 304 — идеальное решение, когда сталь подвергается воздействию химических продуктов. Благодаря высокому сопротивлению межкристаллическому растрескиванию, материал остаётся надёжным даже после сварки.

Эффективность в жёстких химических средах

Материалы проверяются на прочность при воздействии агрессивных химических веществ в химических заводах. Трубы из нержавеющей стали 304 хорошо справляются во всех этих условиях, сохраняя свою прочность при высоких температурах. Коррозионные скорости нержавеющей стали 304 гораздо медленнее, чем у углеродистой стали с удалением радионуклидов в таких средах, что было исследовано. Такая производительность обусловлена её сопротивлением проблемам, таким как точечная коррозия и щелевая коррозия. Когда трубы из нержавеющей стали 304 используются в химически активных и газосодержащих средах, трубы прослужат долго благодаря своей прочности и минимальному обслуживанию.

Исключительная прочность при экстремальных условиях

Стабильность при высоких температурах

трубы из нержавеющей стали 304 обладают очень хорошей сопротивляемостью высоким температурам, до 870°C, и поэтому широко используются в строительстве и дизайне интерьеров. Они особенно хорошо подходят для строительства электростанций и инженерных объектов, где требуется хорошая термическая стабильность. Способность выдерживать высокие температуры без деформации системы гарантирует долговечность и безопасность установок в этих местах.

Возможности работы под давлением

Эти трубы популярны благодаря своей способности противостоять напряжению при упражнениях, а также их пределу прочности на растяжение. Это делает их идеальными для использования в гидравлических системах и других приложениях, связанных с высоким давлением. Соответствуют отраслевым стандартам, таким как ASTM A312/A358, трубы из нержавеющей стали 304 также достаточно устойчивы к коррозии и имеют множество подходящих применений, включая строительные, архитектурные, авиакосмические и декоративные.

Сопротивление удару в промышленных условиях

Высокопрочный 304 нержавеющая сталь 304 более устойчива к коррозии, чем углеродистая сталь. Она может выдерживать до 120 фунтов на квадратный дюйм. FnpT × Гнездо/Гнездо/Гнездо/Гнездо× Гнездо. Соединение/Соединение. Выемка с каждого конца. Тестирование показало, что этот материал превосходит все другие на этом уровне физического воздействия и проходит испытания, которые предотвращают возникновение вмятин или деформации. Неудивительно, что 304 нержавеющая сталь является любимой среди различных отраслей, которые зависят от прочных и надежных материалов для бесперебойной работы своих операций круглосуточно и для продления срока службы их оборудования.

Многогранные приложения в различных отраслях

Использование в строительстве и архитектуре

трубы из нержавеющей стали 304 широко используются в строительстве, так как они не только эстетически привлекательны, но и практичны для широкого спектра различных применений — перил, коммерческого и жилого использования, труб и т.д. Дизайнеры часто выбирают эти опоры, поскольку они не только устойчивы к воздействию окружающей среды, но и предлагают современный, тонкий дизайн. Они являются проверенным временем материалом в городском строительстве и развитии во всем мире. Их долговечность и сопротивляемость коррозии делают их также ценными в фасадном строительстве и конструкционных применениях.

Системы обработки продуктов питания и напитков

В пищевой и напиточной промышленности, нержавеющая сталь 304 провод из стали является одной из самых распространенных труб из нержавеющей стали, однако помимо производства пищевых продуктов и напитков, сталь 304 провод из стали также используется в других отраслях. Эти трубы имеют высоко полированную поверхность и идеально подходят для использования в гигиенически критичных применениях, таких как пищевая и фармацевтическая промышленность. Они нереактивны, поэтому не повлияют на вкус или аромат продуктов питания и напитков, которые вы храните. Их чистота и низкое обслуживание обеспечивают отличную гигиену: нет щелей, видимость продукта во время транспортировки и после мойки… поэтому неудивительно, что их можно найти на пищевых предприятиях по всему миру.

Химическая и морская инфраструктура

трубы из нержавеющей стали 304 широко используются в морских применениях благодаря их высокой сопротивляемости коррозии от соленой воды, бактерий и серы во многих качествах морской воды. Их сопротивляемость химическим веществам делает их идеальной системой для резервуаров и транспортных систем в химической промышленности. Эта гибкость означает, что трубы остаются целыми даже в суровых условиях, предотвращая утечки и загрязнение. С учетом сопротивляемости этим типам сред, трубы из нержавеющей стали 304 также могут использоваться в морской и химической промышленности.

Экономически выгодное предложение на долгосрочную перспективу

Снижение требований к техническому обслуживанию

Долгосрочная ценность труб из нержавеющей стали 304 делает их экономически эффективным вложением по сравнению с другими более дорогими сплавами. Благодаря устойчивости к коррозии, они являются наиболее экономически эффективными на протяжении всего жизненного цикла по сравнению с другими материалами. Большинство пользователей испытывают более низкие общие эксплуатационные расходы при использовании нержавеющей стали 304 по сравнению с другими материалами. Меньшее время простоя для ремонта или замены означает улучшение бизнес-операций и экономию на рабочей силе и запчастях.

Сравнение стоимости жизненного цикла с альтернативными материалами

В вопросах сравнения затрат на жизненный цикл, трубы из нержавеющей стали 304 постоянно признавались выгодным вложением. Оценки стоимости жизненного цикла показывают, что хотя первоначальные затраты выше, благодаря долговечности и низким требованиям к обслуживанию трубы из нержавеющей стали 304 более экономичны в долгосрочной перспективе. Сравнительные данные из различных отраслей промышленности указывают, что затраты на жизненный цикл могут быть на 30% ниже для труб из нержавеющей стали 304. Для любой компании, заинтересованной в максимизации своих долгосрочных операционных затрат, эти трубы окажутся ценным вложением, когда срок службы трубы является ключевым фактором.

ЧАВО

Что делает нержавеющую сталь 304 стальные трубы устойчивой к коррозии?

Превосходная устойчивость к коррозии у труб из нержавеющей стали 304 объясняется их хромо-никелевым составом, который обычно включает 18% хрома и 8% никеля. Это сочетание обеспечивает эффективную защиту от ржавчины и окисления.

Как ведут себя трубы из нержавеющей стали 304 в условиях высоких температур?

трубы из нержавеющей стали 304 обладают замечательной термической устойчивостью, выдерживая температуры до 870°C (1600°F) без нарушения структурной целостности, что делает их идеальными для высокотемпературных приложений, таких как в электростанциях.

Почему трубы из нержавеющей стали 304 популярны в пищевой и напитковой промышленности?

В пищевой и напитковой промышленности трубы из нержавеющей стали 304 популярны благодаря их санитарному соответствию, гладкому поверхностному покрытию и нереактивным свойствам, которые обеспечивают гигиену и не изменяют качество пищи.

Подходят ли трубы из нержавеющей стали 304 для морских условий?

Да, трубы из нержавеющей стали 304 отлично подходят для морских условий благодаря их отличной устойчивости к коррозии от соленой воды, что делает их идеальными для причалов и судовых конструкций.

Каковы стоимостные преимущества использования труб из нержавеющей стали 304?

Использование труб из нержавеющей стали 304 обеспечивает стоимостные преимущества благодаря снижению требований к обслуживанию, более низкой общей стоимости владения и долгосрочной ценности по сравнению с альтернативными материалами, несмотря на более высокие первоначальные затраты.

Оглавление

-

Превосходная коррозионная стойкость нержавеющей стали 304 Стальные трубы

- Состав хром-никель для оптимальной защиты

- Эффективность в жёстких химических средах

- Исключительная прочность при экстремальных условиях

- Стабильность при высоких температурах

- Возможности работы под давлением

- Сопротивление удару в промышленных условиях

- Многогранные приложения в различных отраслях

- Использование в строительстве и архитектуре

- Системы обработки продуктов питания и напитков

- Химическая и морская инфраструктура

- Экономически выгодное предложение на долгосрочную перспективу

- Снижение требований к техническому обслуживанию

- Сравнение стоимости жизненного цикла с альтернативными материалами

-

ЧАВО

- Что делает нержавеющую сталь 304 стальные трубы устойчивой к коррозии?

- Как ведут себя трубы из нержавеющей стали 304 в условиях высоких температур?

- Почему трубы из нержавеющей стали 304 популярны в пищевой и напитковой промышленности?

- Подходят ли трубы из нержавеющей стали 304 для морских условий?

- Каковы стоимостные преимущества использования труб из нержавеющей стали 304?