stainless steel coil suppliers

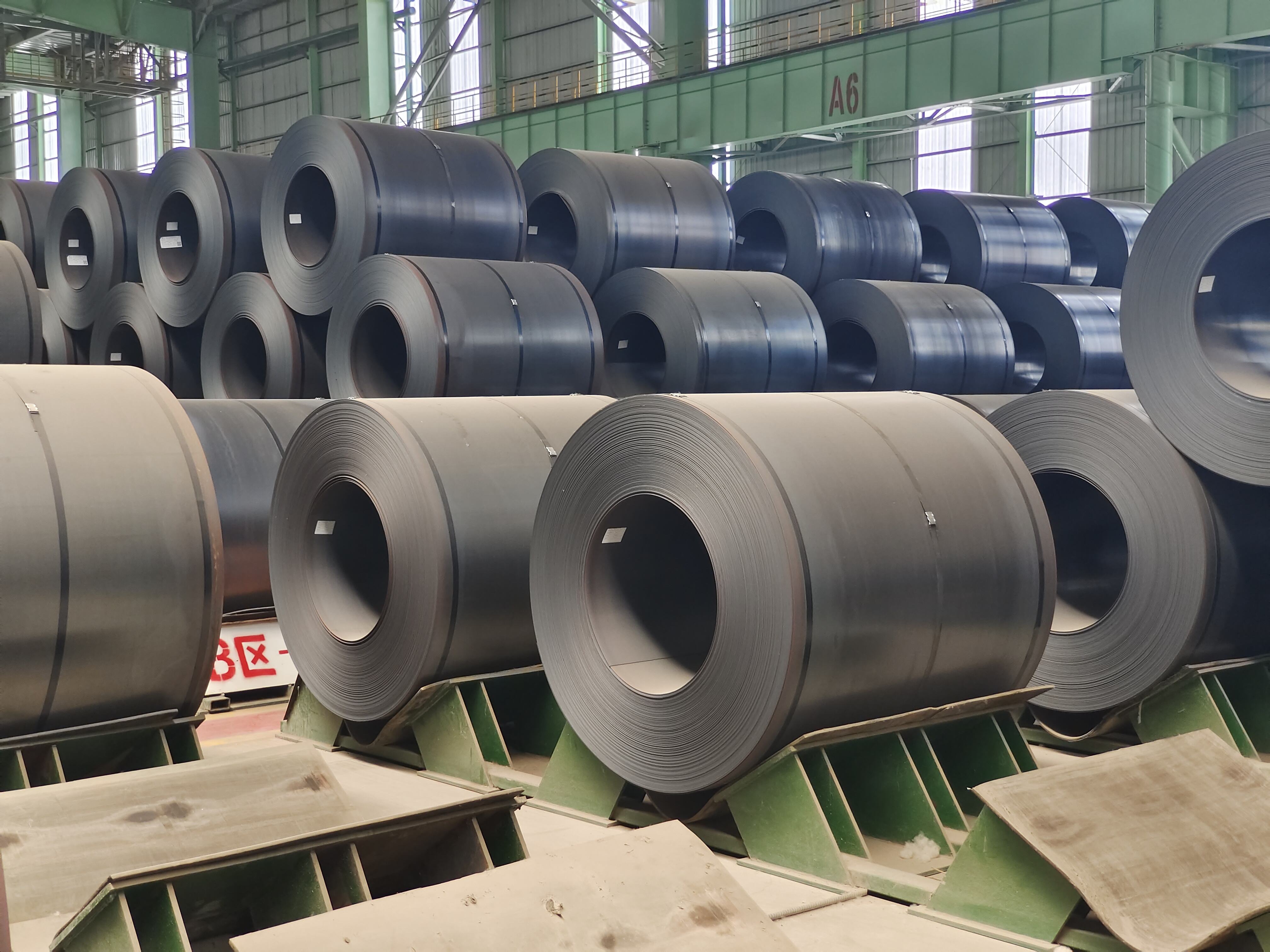

Stainless steel coil suppliers play a crucial role in the global metal industry by providing high-quality stainless steel materials to various sectors. These suppliers maintain extensive inventories of stainless steel coils in different grades, dimensions, and specifications to meet diverse industrial requirements. Modern suppliers utilize advanced processing equipment and quality control systems to ensure consistent product quality, including precision cutting, slitting, and surface finishing capabilities. They source raw materials from reputable manufacturers and undergo rigorous testing procedures to verify material properties such as corrosion resistance, tensile strength, and dimensional accuracy. Many leading suppliers also offer value-added services like custom fabrication, just-in-time delivery, and technical consulting to support their customers' specific needs. Their facilities are equipped with state-of-the-art handling and storage systems to maintain product integrity throughout the supply chain. Additionally, these suppliers often maintain certifications such as ISO 9001 and industry-specific standards to demonstrate their commitment to quality management and customer satisfaction.