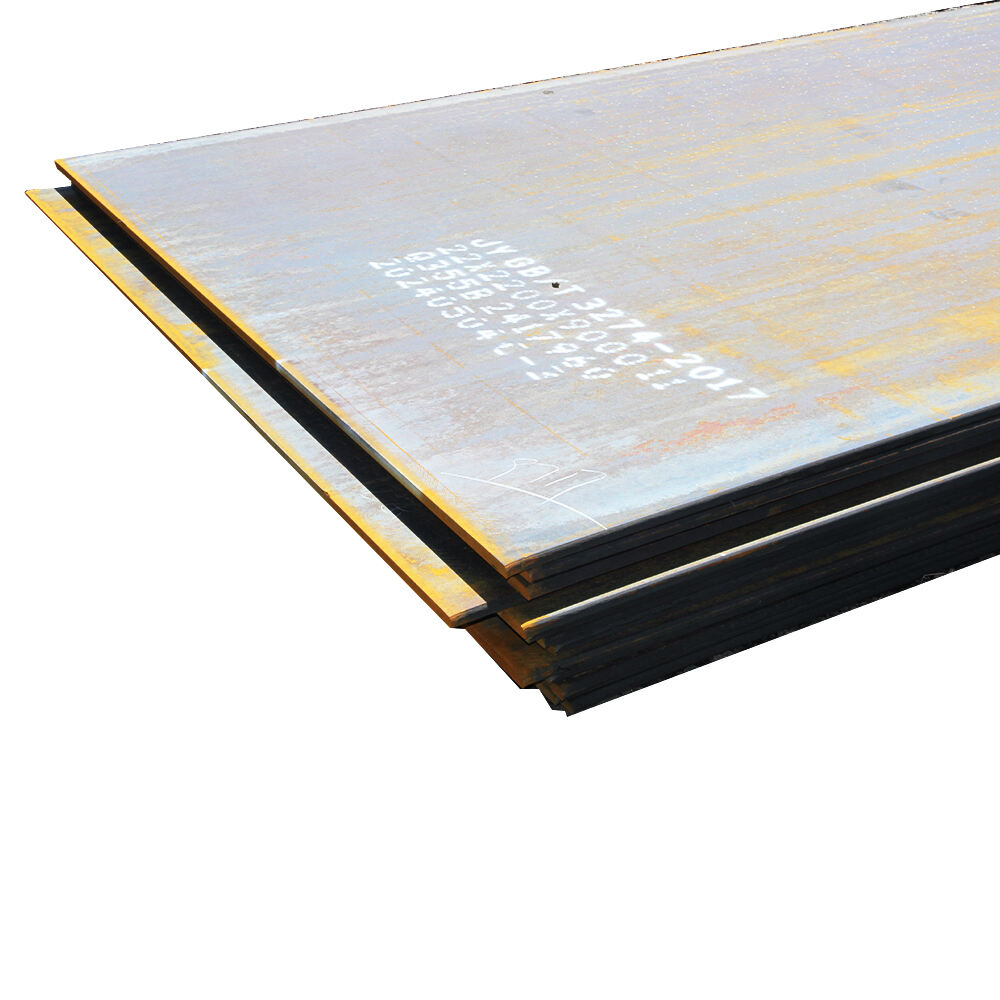

hot rolled steel sheet pile

Hot rolled steel sheet piles represent a crucial engineering solution in modern construction and civil works. These structural elements are manufactured through a high-temperature rolling process, where steel is heated above its recrystallization temperature and formed into interlocking sections. The resulting product features a distinctive Z, U, or straight web profile that enables seamless interlocking between adjacent piles, creating continuous walls of exceptional strength. The hot rolling process enhances the material's mechanical properties, including improved ductility and uniform grain structure, making it ideal for demanding applications. These sheet piles excel in both temporary and permanent applications, providing essential support in deep excavations, waterfront structures, flood protection systems, and underground parking facilities. The manufacturing process ensures optimal thickness distribution and consistent mechanical properties throughout the pile length, resulting in superior performance in various soil conditions. Modern hot rolled sheet piles incorporate advanced metallurgical techniques that enhance corrosion resistance and structural integrity, particularly crucial in marine environments and aggressive soil conditions. Their versatility extends to both driven and vibrated installation methods, accommodating different project requirements and site conditions while maintaining structural integrity.