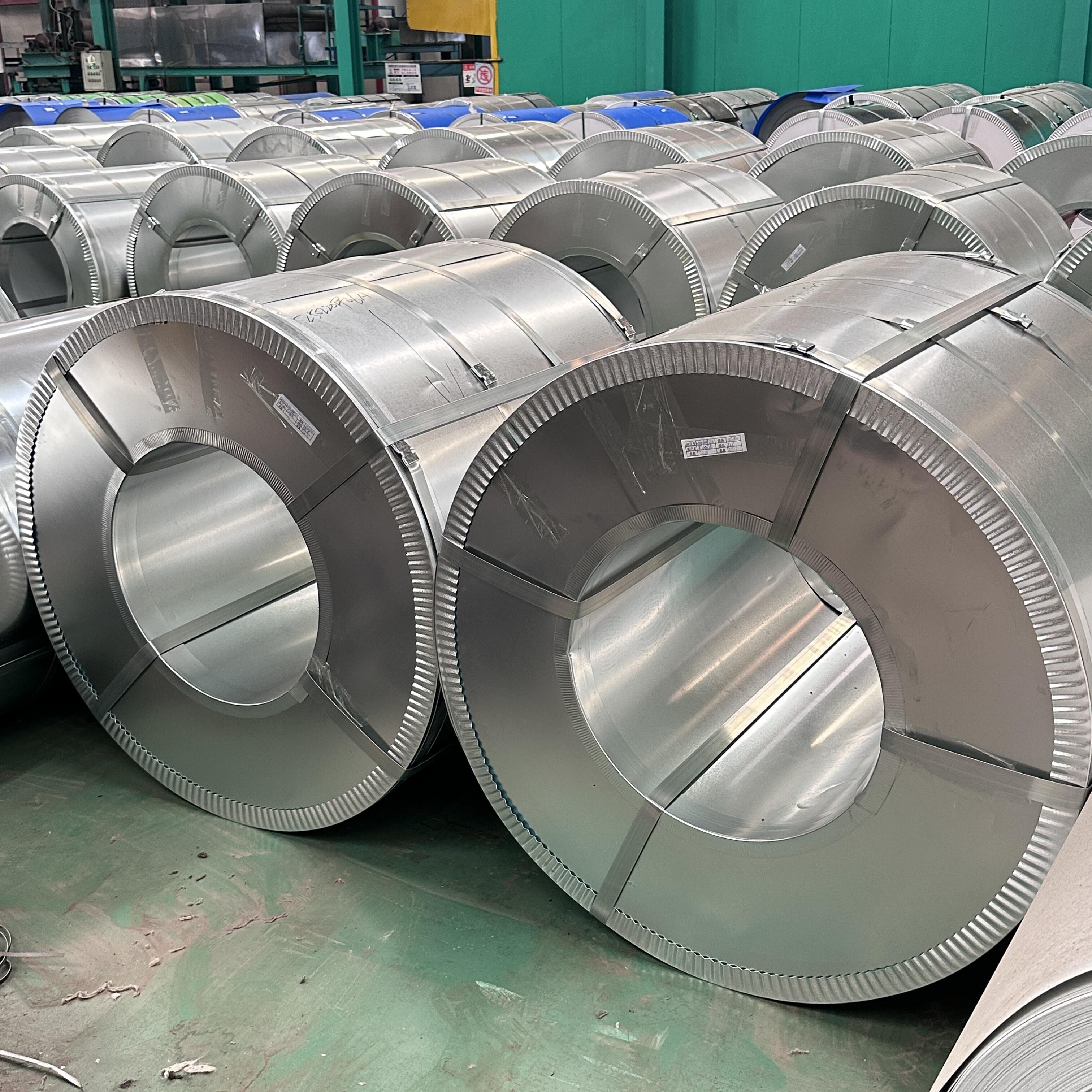

galvanized steel coil

Galvanized steel coil represents a vital innovation in metal protection technology, combining durability with versatile application potential. This engineered product consists of steel sheets or strips that undergo a specialized coating process where zinc is applied to the base metal through hot-dip galvanization or electroplating. The zinc coating creates a sacrificial barrier that actively protects the underlying steel from corrosion and oxidation, significantly extending the material's service life. The manufacturing process ensures uniform coating thickness and superior adhesion, resulting in a product that maintains its protective properties even under challenging environmental conditions. These coils find extensive use across multiple industries, from construction and automotive to agriculture and infrastructure development. The material's inherent strength, combined with its corrosion resistance, makes it ideal for roofing, wall cladding, automotive parts, and various structural applications. Modern galvanized steel coils also feature enhanced formability, allowing for complex shapes and designs without compromising the protective zinc layer. This versatility, coupled with its cost-effectiveness and long-term durability, has established galvanized steel coil as a cornerstone material in contemporary manufacturing and construction practices.